Car Park Flooring

As urbanization accelerates, the demand for durable car park flooring solutions continues to rise, particularly in office complexes, airports, shopping centers, and residential buildings.

Multi-story car parks, require high-quality flooring systems that can withstand heavy traffic, resist weathering, and enhance safety.

Nippon Paint Car Park Deck System provides innovative flooring solutions for car parks, offering superior durability and weather resistance. Additionally, the Nippon Paint FloorShield series features high-performance floor markings, ensuring clear navigation and enhanced safety in parking facilities.

Type of System for Car Park Solutions

Prepared and Treated Concrete

Primer

FloorShield SF Epoxy Primer

- Solvent-free thus no solvent smell

- Low viscosity for penetration

- Excellent wetting of substrate

Intermediate Coat

FloorShield SF Epoxy Mortar

- Impact resistance

- 100% Solid thus zero shrinkage

- Independent of air-drift or environment moisture

Scratch Coat

FloorShield SF Epoxy

OP Textured Finish

- Solvent-free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(First Layer)

FloorShield SF Epoxy Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(Second Layer)

FloorShield SB PU Finish

- Low viscosity provides excellent wetting and over-coating adhesion

- Highly abrasion resistance

- Excellent resistance to fuel, engine oil, and cleaning chemicals

Note: Additional systems are available for Anti-Skid Systems, Orange Peel, Broadcast Sand and PU Anti-skid for enhanced slip resistance.

Prepared and Treated Concrete

Primer

FloorShield SB Epoxy Primer

- Low viscosity provides deep penetration

- Excellent bonding with adhesion promoter added

- Long open time

Finishing Coat

(First layer)

FloorShield SF Epoxy Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(Second layer)

FloorShield SB PU Finish

- Low viscosity provides excellent wetting and over-coating adhesion

- Highly abrasion resistance

- Excellent resistance to fuel, engine oil, and cleaning chemicals

Note: Additional systems are available for Anti-Skid Systems, Orange Peel, Broadcast Sand and PU Anti-skid for enhanced slip resistance.

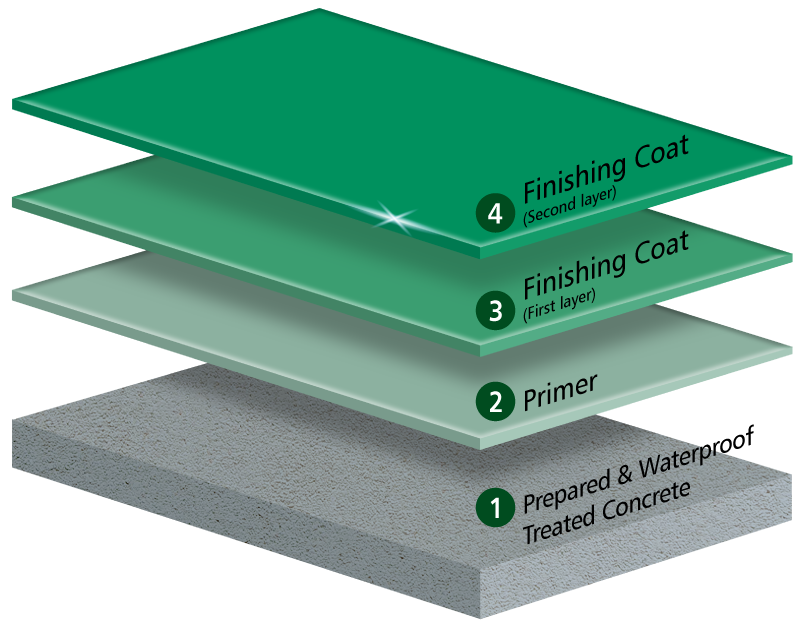

Prepared and Waterproof Treated Concrete

Primer

PrimeCrete WB

- Odourless

- Deep penetration

- Excellent bond strength

- Excellent adhesion

Finishing Coat

(First layer)

FloorShield SB PU Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(Second layer)

FloorShield SB PU Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Note: Additional systems are available for Anti-Skid Systems, Orange Peel, Broadcast Sand and PU Anti-skid for enhanced slip resistance.

Prepared and Treated Concrete

Primer

FloorShield SB Epoxy Primer

- Low viscosity provides deep penetration

- Excellent bonding with adhesion promoter added

- Long open time

Finishing Coat

(First layer)

FloorShield SB PU Finish

- Low viscosity provides excellent wetting and over-coating adhesion

- Highly abrasion resistance

- Excellent resistance to fuel, engine oil, and cleaning chemicals

Finishing Coat

(Second layer)

FloorShield SB PU Finish

- Low viscosity provides excellent wetting and over-coating adhesion

- Highly abrasion resistance

- Excellent resistance to fuel, engine oil, and cleaning chemicals

Overview Of Car Park Deck System

| System | Car Park Deck ID Intermediate Deck |

Car Park Deck BD Basement Deck |

Car Park Deck ED Exposed Deck |

Car Park Ancillaries (Lining / Marking) |

|---|---|---|---|---|

| No. of Coats | 4 | 5 | 4 | 3 |

| Total Thickness (mm) | 0.5 - 0.6 | 5.0 - 5.5 | 0.3 - 0.5 | 0.35 |

| Abrasion Strength (ASTM D4060) |

< 80mg / 1000 cycles | < 80mg / 1000 cycles | < 80mg / 1000 cycles | < 80mg / 1000 cycles |

| Adhesion Strength (ASTM D4541) |

> 1.5N/mm² | > 1.5N/mm² | > 1.5N/mm² | > 1.5N/mm² |

| UV Light Resistance | Excellent (Non-Yellowing) |

Excellent (Non-Yellowing) |

Excellent (Non-Yellowing) |

- |

| Shore D Hardness (ASTM D2240) |

> 75 | > 80 | - | - |

| Compressive Strength (ASTM D638) |

> 85MPa | > 40MPa | - | - |

| Strength (ASTM C580) |

> 40MPa | > 20MPa | - | - |